JTU, in strategic collaboration with ZSW, successfully participated in NEPCON Thailand 2025 at the Bangkok International Trade and Exhibition Centre (BITEC), marking another milestone in our commitment to advancing electronics manufacturing across the region. In our booth, we unveiled a comprehensive suite of high-performance solution tailored for smart factory environments. The showcased equipment included:

- JTU SS Series Solder Paste Management System – An innovation, making its debut in Thailand.

- JTU C Series Conformal Coating Machine – Upgraded with enhanced software features.

- ZSW Pro Series Selective Soldering Machine – First showcase in Thailand, with upgrade-ready integration

(Ft. Sono-Tek ultrasonic fluxing system, GSE nitrogen generator)

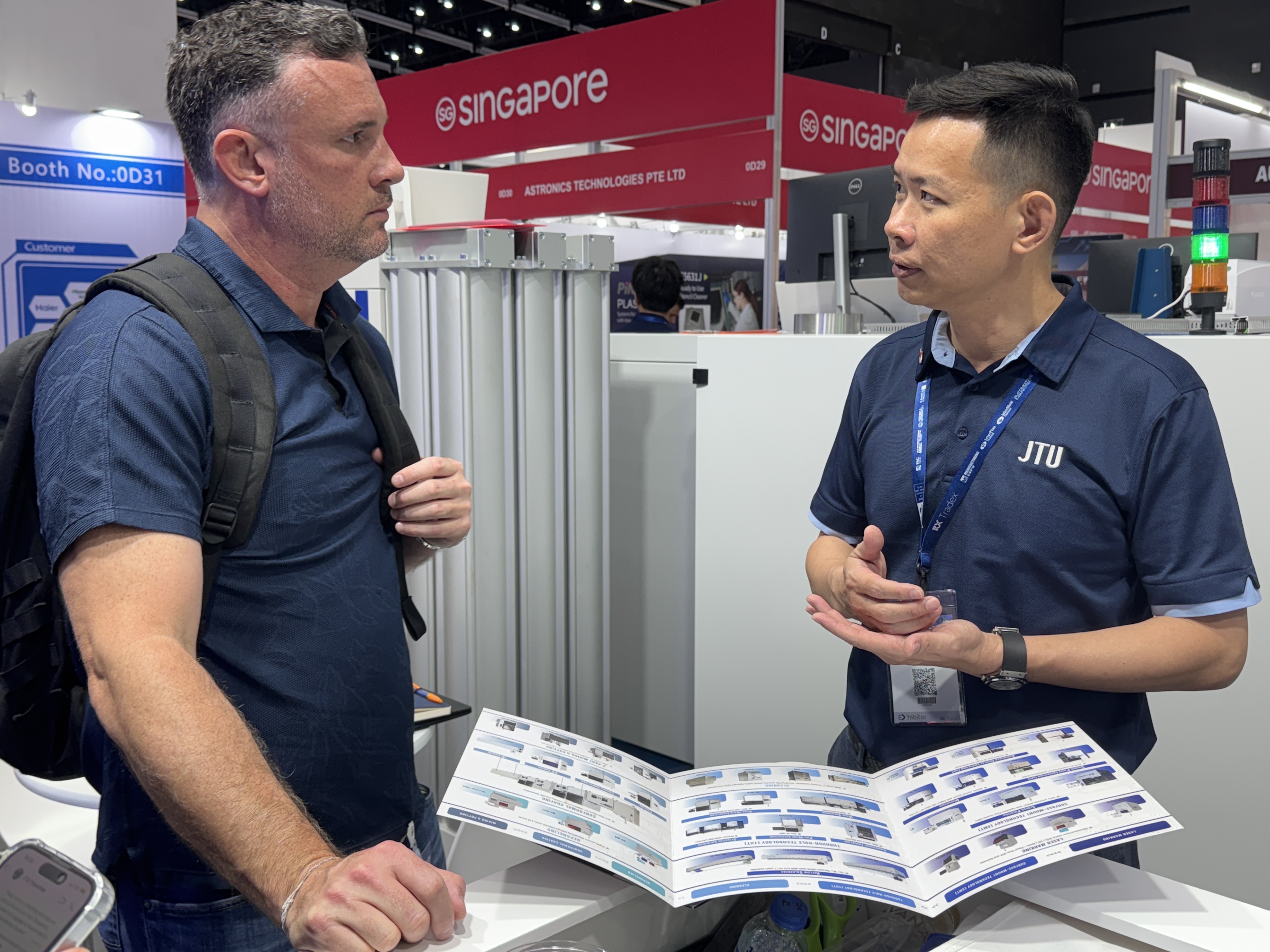

NEPCON Thailand 2025 served as a key platform for JTU and ZSW to reinforce our regional presence and connect directly with customers seeking end-to-end electronics production solutions. We aim to expand local support develop tailored training programs and strengthen after-sales services across Thailand and neighboring markets.

The booth attracted significant attention from industry professionals, eager to experience our integrated solutions designed to streamline SMT processes and improve production reliability. This successful partnership with ZSW at NEPCON Thailand reinforces our dedication to bringing intelligent, sustainable, and high-performance solutions to Southeast Asia’s growing electronics sector.

Our booth attracted a steady stream of visitors, many drawn by our live demonstrations that tackled manufacturing challenges. These hands-on sessions served as a gateway to deeper technical conversations, where we showcased innovative solutions like the JTU Solder Paste Management System – a breakthrough in SMT process control. Its integrated quality assurance and traceability capabilities resonated strongly with visitors focused on process stability and data driven manufacturing. At the same time, the ZSW Pro Series Selective Soldering Machine sparked interest for its exceptional cost efficiency, made possible by reduced flux usage and minimal solder dross. With an electromagnetic pump system delivering a free vortex, stable wave, the system ensures both soldering consistency and waste reduction.

We sincerely thank all visitors, customers, and partners who contributed to the success of this event. We remain committed to delivering next generation manufacturing excellence!

Check out the video for a short recap: CLICK ME TO VIEW