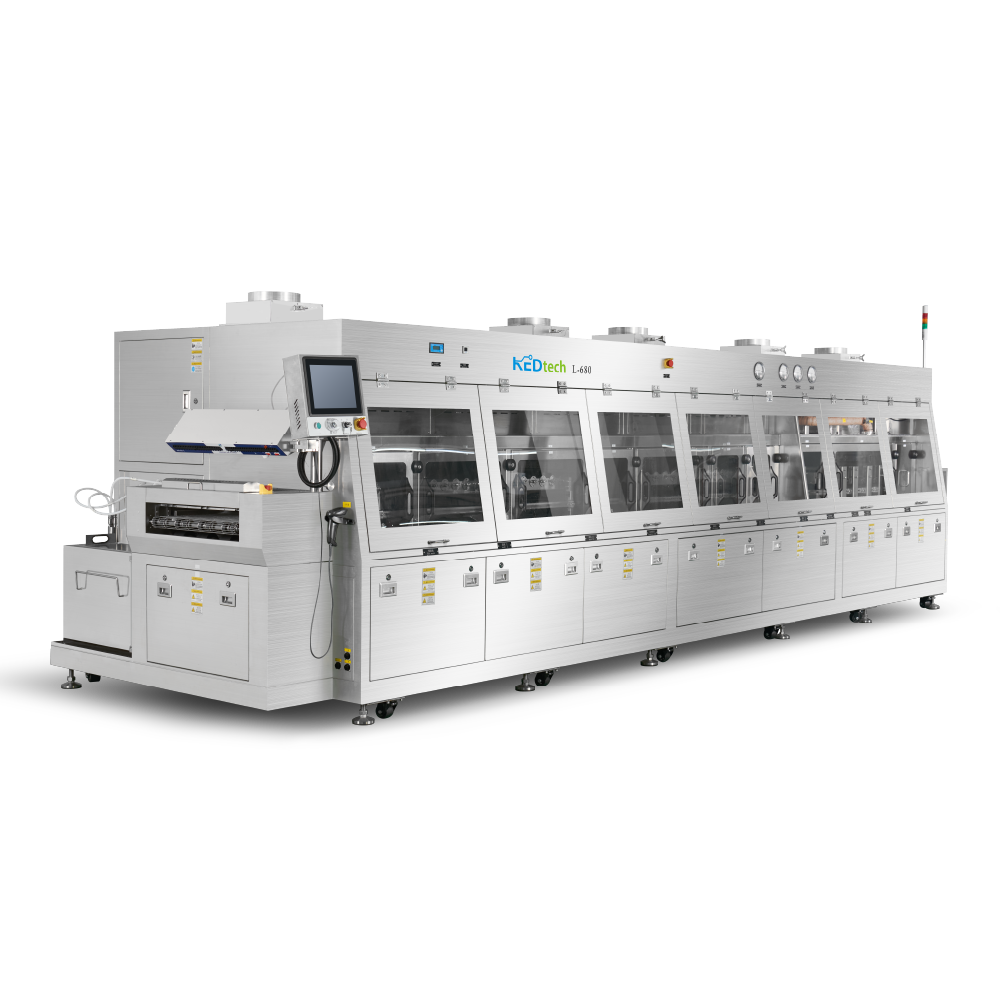

KED

L-580/680

- Fully automatic inline cleaning machine.

- Suitable for high capacity products residual cleaning.

- Full set features including cleaning, rinsing and drying tgo maximize cleaning performance and process flexibility.

- Customized conveyor mesh design available for different products. Conveyor equipped with sensor, monitoring board counter.

- Stainless steel cabinet (SUS304) is anti-corrosion, and the cleaning agent can be heated to a higher temperature in order to get a wider process window.

- High efficiency blower to clear chemicals from products and conveyor to reduce chemical consumption.

- The machine is equipped with a filter system to filter those residues on product in order to prevent nozzle blockage.

- High pressure hot air knives are specially designed to dry water fast and thoroughly and avoid water mark after drying.

- Machine operations are controlled by PLC & touch panel for parameters setting.

- Quick edit available and a variety of different process parameters can be stored according to the different PCBA model set.

| Machine Dimension | L5800 x W1854 x H1800 mm / L6800 x W1854 x H1961 mm |

| Machine Weight | 3000 kg / 3400 kg |

| Mesh Speed | 10 cm/min - 150 cm/min |

| Maximum Cleaning Size | L400 x W600 × H100 mm |

| Mesh Size | Width: 600 mm, Height: 900 (-20/+50) mm |

| DI Water | DIW: 5-15L/min, pressure: >0.3MPa |

| Cleaning Tank | 190L / 290L |

| Cleaning Pump Power | 7.5kW / 7.5 kW x2 |

| Cleaning Filter | 10μm |

| Rinsing tank | Pre-Rinse: 80L, R1: 170L, R2: 80L / Pre-Rinse: 75L, R1: 150L, R2: 75L |